Customer Introduction

The case shared this time is a comprehensive treatment project for welding fume of a large multinational heavy industry enterprise. The customer mainly produces tower cranes and crawler cranes. The customer is an enterprise with great comprehensive strength and influence in the engineering machinery industry. It is also a large multinational enterprise and one of the largest crane groups in the world.

Project Background

Our company comprehensively treats the welding fume of the boom line of the enterprise. The boom lines are all large carbon steel steel components. A large amount of fume is generated during welding, and the welding position is not fixed.

Welding method: MAG gas shielded welding, argon arc welding, etc. The welding workpiece is placed on the ground for welding.

Pollution type: metal welding fume.

Operation characteristics: large welding workpiece and unfixed welding point.

Solution

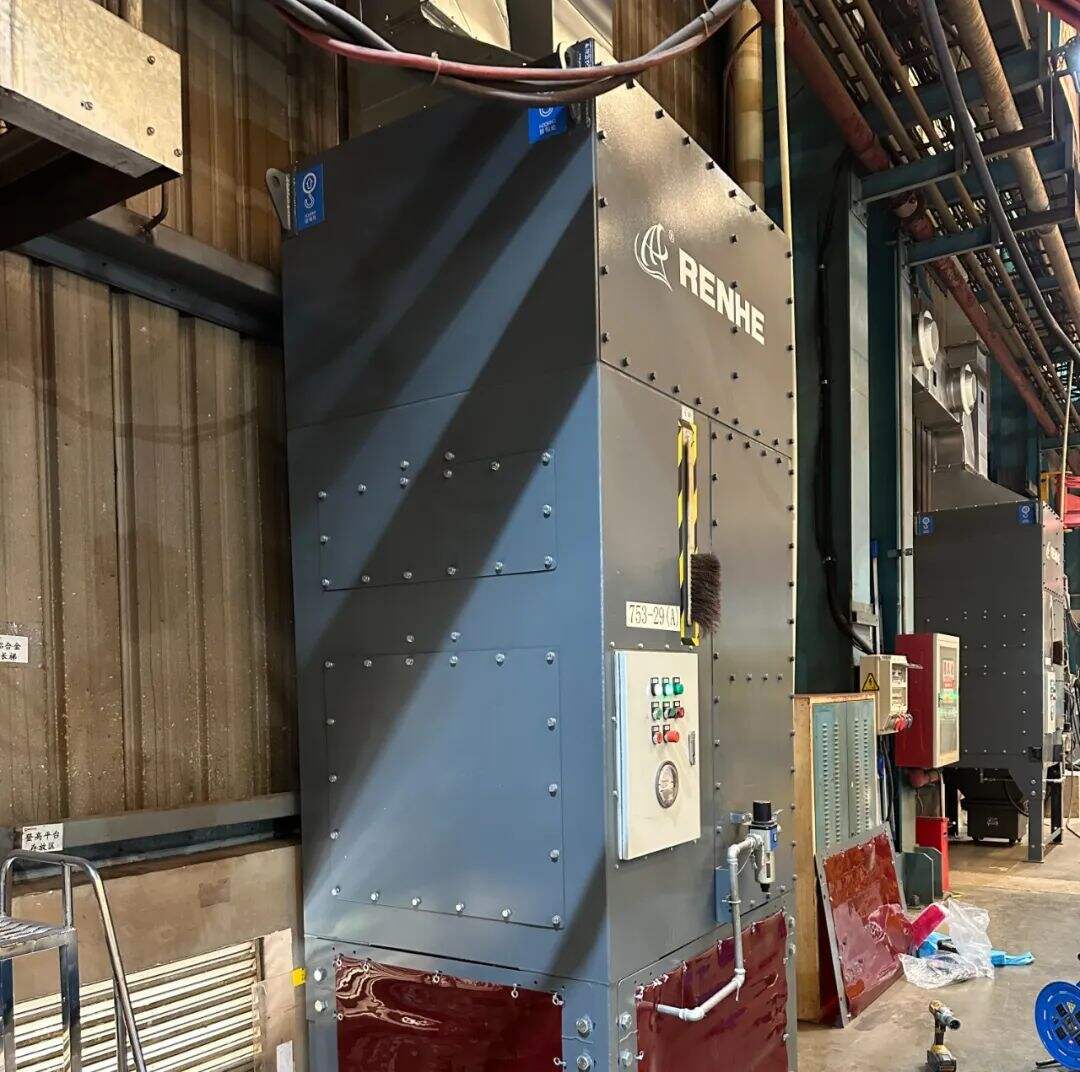

Based on the application experience and technical precipitation accumulated in various industries over the years, the Renhe team tailored a welding fume filtration solution for the foreign-funded heavy industry enterprise according to the actual welding position on site and after sufficient communication with the customer:

1. A distributed blow-by welding fume collection device is set between the columns of the welding workshop. The height of the blowing port is 4 meters and the height of the suction port is 9 meters.

2. Two single devices are set up in opposite directions to form a blowing and suction airflow, and the welding fume is purified by locally manufacturing a drop circulation method. The functional coverage area of each set of equipment is not less than 24m*6m.

3. 70 welding fume collection devices are arranged, each device handles an air volume of 5000m³/h, totaling 350000m³/h;

4. A group of welding fume collection devices can be opened separately on site according to the actual working conditions, saving energy while ensuring the treatment effect.

Governance Effectiveness

After comprehensive treatment of the fume in the on-site welding workshop, it was tested that the concentration of electric welding fume in the workshop was <2mg/m³, which met the standard requirements of GBZ2.1 2019 "Occupational Exposure Limits of Harmful Factors in the Workplace-Chemical Harmful Factors" (<4mg/m³)